The nitrogen generator for petroleum & natural gas is mainly used in protection, transportation, covering, pipeline replacement, rescue, maintenance, nitrogen injection, oil recovery, dilution nitrogen content, etc.

Flammable, explosive, and oxidizing substances exist everywhere in the refining industry. Safe and inert nitrogen is always used in material transportation, catalyst protection, pipeline purging, material packaging, and accident handling.

According to the classification of raw materials in the chemical industry, our nitrogen production equipment products have covered every aspect of the chemical industry, such as synthetic resins, fibers, plastics, fertilizers, chlor-alkali, calcium carbide, catalysts etc.

Synthetic resins, fibers, plastics, fertilizers and other chemical industries in flammable, explosive, oxidizing substances everywhere, in material transportation, catalyst protection, pipeline purging, material packaging, accident treatment, etc., almost all use inert nitrogen.

RICH has advanced food storage and liquid nitrogen preservation technology. Our equipment covers the main domestic granaries, effectively inhibiting the survival of pests and diseases. Our blanketing technology has been widely used in the beer and food packaging. The introduction of nitrogenous sealing technology has greatly extended the product preservation cycle, and relieved the user's worries caused by unsalable products.

RICH's coal mine nitrogen injection system is a series of innovative products developed for the demand of underground coal mining, which can effectively prevent the gas explosion and coal dust explosion in underground coal mines, and provide a strong guarantee for underground coal mining operations. We provide horizontal portable nitrogen injection products for underground coal mining operations, especially ultra-large nitrogen injection products.

The application of nitrogen not only improves the quality of metal processing products,but also promotes the improvement of production efficiency and the reduction of costs.With the advancement of metal processing technology,the application of nitrogen in this field is expected to be more widely promoted and deepened.Nitrogen plays a vital role in the metal processing industry and has a wide range of applications,

mainly including the following aspects:

1. Laser cutting

As an auxiliary gas ,nitrogen prevents metal oxidation,ensures cutting quality,and removes molten metal....

2. Heat treatment

As a protective gas,nitrogen prevents oxidation corrosion when teh mental is heated,and is suitabel for special processes.

3. Welding

Use nitrogen protection to prevent weld oxidation,especially in stainles steel welding.

4. Casting、powder metallurgy

Nitrogen as a protective atmosphere improves the quality of finished products and improves the structure of castings.

5. Storage and transportation

Nitrogen creates an oxygen-free environment and effectively prevents oxidation and corrosion of metal materials.

The use of nitrogen ensures a clean and sterile environment, which is essential for the production of pharmaceutical products. In addition, nitrogen is ideal for regulating oxygen concentrations during pharmaceutical packaging. Nitrogen generators for the pharmaceutical industry are mainly used in production, storage, packaging, packaging and other fields. The medical nitrogen equipment is developed according to GMP specifications which has low operating costs, stable nitrogen purity and easy use compared with cylinder nitrogen (or liquid nitrogen).

Nitrogen plays a variety of key roles in the production of lithium batteries. It is used to prevent oxidation, stabilize the atmosphere in the coating area, control the reaction environment to ensure battery life, achieve vacuum or atmosphere protection, clean battery components, bake to remove environmental moisture, prevent welding oxidation, prevent thermal runaway, and prolong battery life. These ensure the performance, safety, and stability of lithium batteries.

The main applications are as follows:

1.Photovoltaic solar cell production

eate a pure, oxygen-free atmosphere and prevent contamination of photovoltaic materials by impurities and oxygen, which helps to ensure the high efficiency and long life of solar cells. In the manufacture of solar cells, high-purity nitrogen is often used, and a nitrogen purity of 99.999% (5N) or higher is usually required to ensure that the manufacturing process is not contaminated by oxygen and other impurities.

2.Lithium battery production.

In lithium battery manufacturing, nitrogen is used to maintain an oxygen-free or hypoxic manufacturing environment, prevent unwanted reactions between highly reactive materials and oxygen in the battery, and improve the safety and stability of the battery. In lithium-ion battery manufacturing, industrial-grade nitrogen (99% to 99.9% purity) is usually sufficient to maintain an oxygen-free or hypoxic environment to prevent oxygen from negatively affecting the materials in the battery.

3.Energy storage systems

In electric energy storage systems, nitrogen can be used as a protective atmosphere for the energy storage system to prevent oxidation and corrosion in batteries or supercapacitors. In electric energy storage systems, the purity requirements for nitrogen are often application-dependent. High purity nitrogen is often required to prevent oxidation and corrosion in batteries or supercapacitors.

In battery production and energy storage, the use of high-purity nitrogen is essential to ensure product quality, improve production efficiency and ensure safety.

RICH's nitrogen vulcanization process replaces the traditional superheated water vulcanization process, and has been successful in the rubber/tire industry. Nitrogen vulcanization technology advantages:

Reduce the necessary investment in utilities for the steam generation process, and reduce the emissions of NOX and COX, so as to achieve the purpose of energy saving and environmental protection

Reduces the chance of glue deficiency, delamination and bubbles in tire vulcanization, and improves the quality of tires

Small heat loss, saving energy and reducing costs

High-purity nitrogen prevent the devices from being premature aging under the action of oxygen

Tire performance indicators have been improved in mileage, durability, uniformity, and press-through capacity

Easy to use, the pressure is adjustable within a certain range

Nitrogen can be recycled with a recovery rate of about 40%.

The electronics manufacturing industry is an industry which cover a wide range of fields, encompassing the design, production, and assembly of electronic components, semiconductors, electronic devices, and electronic systems. This industry strives to produce a diverse range of electronic products such as computers, mobile phones, televisions, semiconductor chips, electronic components, communication devices and so on. Electronics manufacturing involves advanced process technologies, which aims at creating products with exceptional performance, superior quality, and high reliability to meet the ongoing demands of the global market. Also, it serves as a significant driver of technological innovation. Within electronics manufacturing, the application of nitrogen sealing technology is extensive, with some common applications outlined below:

Welding and Brazing

In the manufacturing and assembly of electronic components, welding and brazing are common processes. Using nitrogen for these processes reduces the presence of oxygen, prevents oxidation reactions, and enhances the quality and stability of connections. This is crucial for producing high-quality electronic components.

Vacuum Packaging

When manufacturing integrated circuits (IC) and other electronic components, they are typically encapsulated in a vacuum or controlled atmosphere. Nitrogen can be used to create a high-purity atmosphere. This ensures no impurities enter during the packaging process, therefore maintaining the components' performance and reliability.

Silicon Wafer Manufacturing

In the semiconductor industry, the manufacture of silicon wafers is critical. Nitrogen is utilized for annealing and other process steps to improve wafer quality, reduce flaws and enhance the performance of electronic devices.

Electronic Device Assembly

During the assembly and testing of electronic equipment, nitrogen can be employed to create a sterile environment, preventing contamination from dust, impurities, and microorganisms. This is vital for manufacturing high-demand electronic devices.

Electronic Components Packaging

In the packaging process of electronic components, nitrogen is typically used to fill the atmosphere within the packaging material, which can reduce the presence of oxygen, prevent product oxidation, maintain product performance and extend its lifespan.

In the field of electronics manufacturing, it is crucial to strictly control the purity and usage of nitrogen during the nitrogen sealing process. Typically, the nitrogen used requires an extremely high purity level, exceeding 99.999%. The usage of nitrogen needs to be adjusted based on specific application scenarios and process requirements. The primary objective is to maintain a low-oxygen environment to prevent oxidation reactions. Therefore, it’s necessary to appropriately set the nitrogen usage according to the specific needs of each stage and different equipment on the production line, which to ensure the high-quality production of electronic components.

Optical fibers are extremely fine filaments drawn from special plastic and quartz glass, they are fragile and susceptible to oxidation and dust. Oxidation and dust contamination will affect the efficiency of optical fiber for signal transmission, and in serious cases, it will lead to signal interruption. Nitrogen can effectively isolate the optical fiber from the air, so as to ensure the transmission performance and service life of the optical fiber.

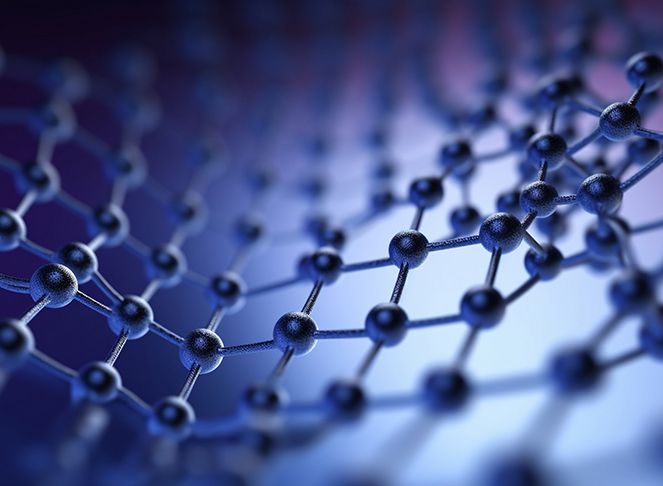

In the manufacturing process of graphene, it is necessary to use nitrogen to protect graphene from oxidation and pollution, to improve the performance and stability of graphene.

Nitrogen displacement is used to purify methane and other gases used in production to ensure the safety of the preparation process and the quality of graphene.

To improve production efficiency, pure nitrogen, as a high-energy ion beam, can provide enough energy to generate these carbon vacancies and defects, so as to achieve efficient preparation of graphene.

Nitrogen-assisted molding is widely used in the automotive industry to manufacture complex parts such as bumpers, instrument panels, and seat frames.

By taking on the assisted molding technology, automotive parts can be molded with high quality, high strength and complex shapes in a solid line at a lower cost and with a short production cycle. This technology helps to improve the safety performance and appearance quality of automobiles, while reducing production costs and reducing scrap.

Nitrogen-assisted molding technology can reduce harmful gas emissions in production and reduce environmental pollution.

During the high-temperature molding process, nitrogen can replace oxygen in the air, avoiding oxidation and scorching of the product.

Due to the low thermal conductivity of nitrogen, the molding temperature can be lowered and energy consumption can be reduced.

Nitrogen is an inert gas, which is used in the field of ships and offshore engineering for pipeline purging, material transportation, or oxidizing, flammable and explosive chemicals, oils, liquefied natural gas LNG, liquefied petroleum gas LPG, ethylene LEG, methanol, and hydrogen protection and pressure holding.

Ships using nitrogen include: chemical tankers, product tankers, food carriers LNG / LPG / LEG carriers & Bunkering vessels dual-fuel vessel FGSS system, FSRU / FPSO / FLNG,PSV / OSV / VLEC / VLGC etc.

RICH's vacuum PSA technology has made a breakthrough in the paper industry. We have developed a complete oxygen production product for the paper industry, which can help users effectively reduce costs in gas, improve product quality, saves energy and achieve environmental protection.

The oxygen purity meets the requirements of the bleaching process. The equipment is simple to use, and the control is convenient.

Oxygen-enriched aeration activated sludge process: suitable for the denitrification upgrade of existing activated sludge treatment plants.

Ozone from surface waters: Ozone that can be used for surface water such as canals, rivers, lakes and artificial reservoirs.

Fish farming: When oxygen is applied, the density and number of fish species can be increased several times, while the cost of water treatment can be reduced.

Industrial oxidation process: sulfide oxidation in paper bleaching, hydrogen peroxide production, etc.

The demand for industrial gases is increasing as the production processes for float, container, flat plate, optical fiber and specialty glass products are being upgraded.

Compared with the traditional combustion with air as raw material, the oxy-fuel combustion greatly improves the heat, which optimizes the quality of user products and improves production, reduces combustion impurities, prolongs the service life of the combustion furnace, and the oxy-fuel combustion is more energy-saving and environmentally friendly.

Nitrogen is mainly used in the glass industry to prevent surface oxidation in the glass manufacturing process and to cool the furnace.

By using oxygen to support combustion, the combustion temperature is high, which is reduces the amount of flue gas and harmful substances generated in the process.

The use of oxygen increases the furnace output and extends its service life, which is good for the environment.

Oxygen purging, improving the combustion rate, improving the yield of castings, etc.

Improve productivity, save energy and reduce consumption. Oxy-fuel combustion can increase the furnace temperature, increase the furnace capacity by 20~40% compared with the use of air, reduce fuel consumption by 30%, and prolong the service life of the furnace.